India’s PV capacity surpasses 68 GW

India will have to add more than 30 GW of solar capacity per year to meet the 293 GW PV target in its optimal energy mix for 2029-30. The nation had installed 68 GW of PV capacity by May 31, 2023.

Japan’s 16th solar auction concludes with lowest bid of $0.065/kWh

Japan’s latest procurement exercise was open to PV projects above 250 kW in size. The lowest price came in at JPY 9 ($0.065)/kWh, with 119.7 MW of allocated capacity.

Indian state launches tender for 100 MW of floating solar

The Punjab Energy Development Agency (PEDA) is seeking developers to set up 100 MW of floating solar capacity across the Indian state of Punjab.

The Hydrogen Stream: Scientists use perovskite compound to store ammonia

Japanese scientists have developed an organic-inorganic halide perovskite compound for the chemical storage of ammonia (NH3), while Bosch is preparing to exhibit new products in the hydrogen value chain.

Chinese PV Industry Brief: Tongwei plans 16 GW PV cell factory

Tongwei says it will build a new 16 GW solar cell factory in Meishan City, China’s Sichuan province.

New soda ash factory in China to reduce solar glass prices

Inner Mongolia Berun Group recently inaugurated a new soda ash factory in China. pv magazine spoke about the impact of the new facility on solar glass prices with Marguerite Morrin, research director for OPIS’ Chemical Market Analytics. She said the facility will produce natural soda ash, which is cheaper than synthetic soda ash.

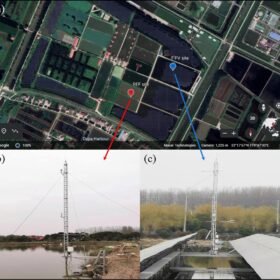

Effects of floating photovoltaics on radiation, energy flux on lakes

A group of researchers from China assessed the impact of floating PV systems on the radiation, energy flux, and driving forces on lakes under varying meteorological conditions. It found that the impact of a PV array on the sensible heat flux of a lake is 1.5 times that of a natural lake.

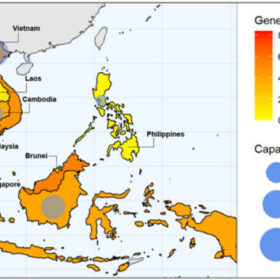

US researchers assess potential for floating solar in Southeast Asia

The US National Renewable Energy Laboratory (NREL) and its partners have assessed the technical potential for floating PV throughout Southeast Asia.

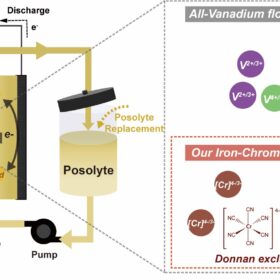

Iron-chromium redox flow battery with high energy density

Researchers led by Korea’s UNIST developed a new redox flow battery concept that utilizes iron and chromium ore for redox chemistry. The proposed battery configuration may reportedly achieve a stable lifetime of 500 cycles, and a high-energy density of 38.6 Wh L−1.

Intersolar 2023: ‘Europe needs China to rebuild its solar industry’

Alessandro Barin, CEO of FuturaSun, spoke with pv magazine at the recent Intersolar 2023 trade show about the PV module manufacturer’s plans to expand in China and its home market of Italy. He said European and Chinese manufacturers take different approaches to new factories, but the two sides will need to come together to build a sustainable global supply chain.