A group of researchers from Germany has proposed to replace titanium (Ti) bipolar plates (BPPs) in proton exchange membrane (PEM) water electrolyzers with plates based on coated stainless steel (ss) in an effort to reduce current high manufacturing costs. “PEM electrolyzers currently use costly materials, such as titanium and platinum group metals (PGM), due to the harsh oxidative conditions within the cells,” the scientists emphasized, noting that BPPs account for up to 60% of the stack costs.

They used plates with a circular shape and an active area of 86 cm2 provided by Norwegian hydrogen specialist Nel Hydrogen and coated them with stainless steel and niobium (Nb) through vacuum plasma spraying (VPS). “Before starting the spraying procedure, the substrates were sand-blasted with silicon dioxide (SiO2) powder to increase surface roughness as well as adhesion of the coating powders and preheated to 250 C in the vacuum chamber,” they explained. “The Nb layers were deposited by applying a power of 1.0 kW for 15 min, so that a layer thickness of 1.4 μm was achieved, which was sealed using the aforementioned capillary sealing process.”

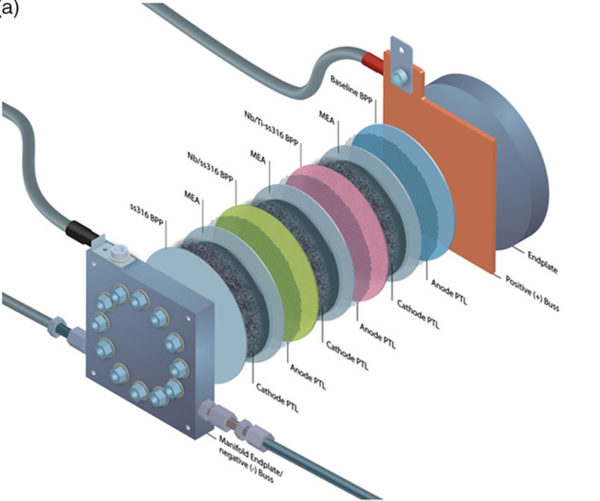

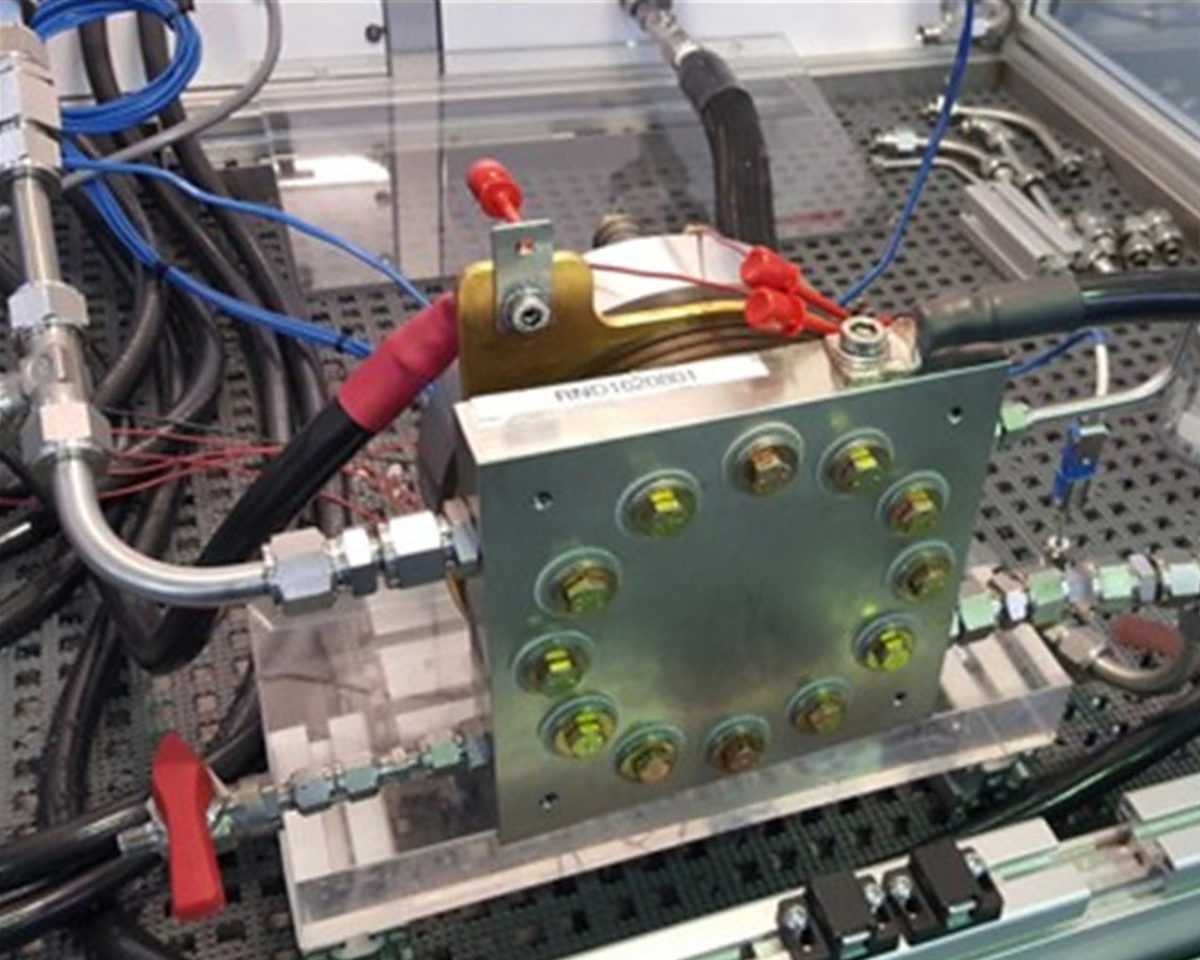

The stack was assembled in a four-cell configuration with different anode BPP and it was operated in a test stand that is used for standard PEM electrolyzers. During the 14,000 h test, the cells with coated ss-BPP exhibited performance of around 1.9 V at 1 A cm−2, which the scientists described as similar to that of a commercial baseline cell. “The test protocol did not include any previously planned shutdown periods, yet these events occurred triggered by common test stations issues and common challenges found when operating test-rigs for such a long time,” they specified.

Image: German Aerospace Center (DLR), Advanced Energy and Sustainability Research, Creative Commons License CC BY 4.0

The performance of the Nb/ss-BPP plate was compared to that of an identical plate integrating Ti and both coatings showed no sign of corrosion and were able to fully protect the substrate during operation. According to the scientists, both plates performed comparably to the baseline material from Nel Hydrogen and their performance reached a cell efficiency of nearly 78%, with a degradation rate of only 1.2%. “However, from a cost perspective, the Nb coating offers a clear advantage over Nb/Ti, as it requires two processing steps to apply and form a thick and stable oxide layer,” they stressed.

Popular content

The scientists described the stack design in the paper “Long-Term Operation of Nb-Coated Stainless Steel Bipolar Plates for Proton Exchange Membrane Water Electrolyzers,” published in Advanced Energy and Sustainability Research. “The results achieved can mark a turning point for future electrolysis research, in which steel-based stack components are seen as the new standard, laying the foundation for the massive cost reduction in PEM electrolyzers and thus an essential factor for the production of competitive green hydrogen.”

The research group comprises academics from the German Aerospace Center (DLR), the University of Applied Sciences Esslingen, the Forschungszentrum Jülich GmbH research center, and Nel Hydrogen itself.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.