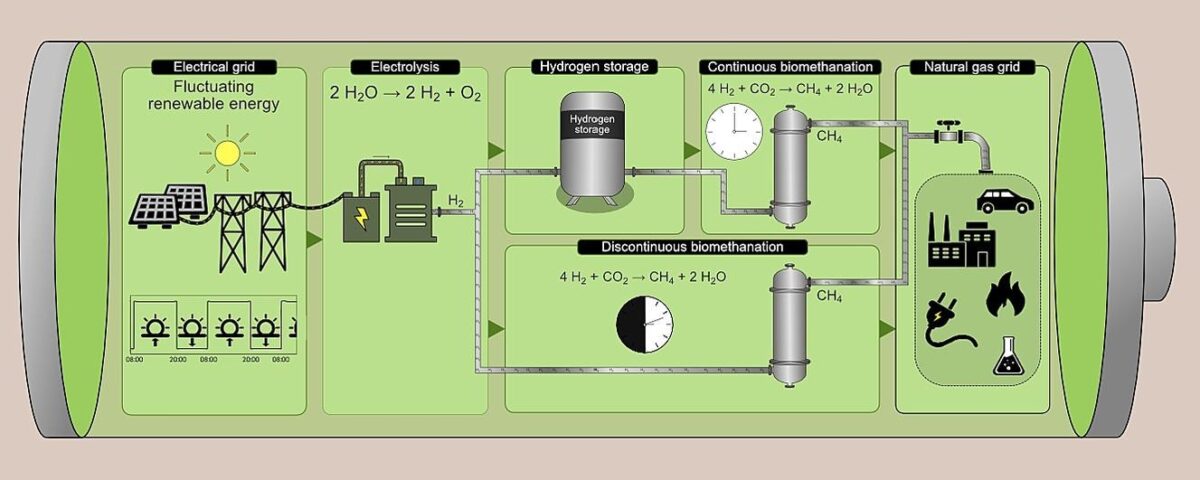

Scientists from Denmark’s Aarhus University have demonstrated the possibility of producing biomethane via photovoltaics. They considered how to implement the biomethanation process in PV-driven operations, where activity is shut off due to the lack of solar radiation.

Biomethanation is the processing of organic materials into biogas, primarily composed of methane (CH4) and carbon dioxide (CO2). In this process, hydrogen gas (H2) plays a significant role as a substrate for microbial reactions and a part of the final product.

“As an alternative to battery energy storage, the utilization of solar PV energy to produce H2 by the water electrolysis process has been proposed,” the scientists explained. “H2 may be used as a building block to produce other fuels and chemicals, [such as biomethane]. Biomethane, with typical concentrations above 98 vol% CH4, is well suited for injection into natural gas grids.”

To demonstrate the feasibility of producing biomethane in discontinuous PV terms, the academics first gathered solar data from the California Flats Solar Park – a 280 MW PV plant located in Monterrey County, California.

“At the commencement of the PV-driven discontinuous operating mode, it became evident that the TBR did not achieve the same biomethanation conversion efficiency as the prior continuous mode of operation,” the academics explained. “However, after six days of following this discontinuous operating strategy, the reactor recovered to its baseline performance on day 7.”

Image: Aarhus University, Energy Conversion and Management, Creative Commons License CC BY 4.0

According to academics, in the first four days of the discontinuous operation, H2 concentrations ranged from 10% to 40% in the biomethane product gas. However, by the sixth day, H2 content within the biomethane was less than 2%, as desired. Furthermore, on days seven to 12, this quality was achieved within 16 minutes after start-up; on days 13 to 21, it was achieved instantaneously; and on the last days, it was completed within 20 minutes from operation start.

“During the 12-hour standby periods, accumulated acids from the operation period degraded 58.44 % to biogas,” the scientists further explained. “Thus, the standby periods could synergistically be exploited as a clean-in-place technique to remove accumulated acids and biomass.”

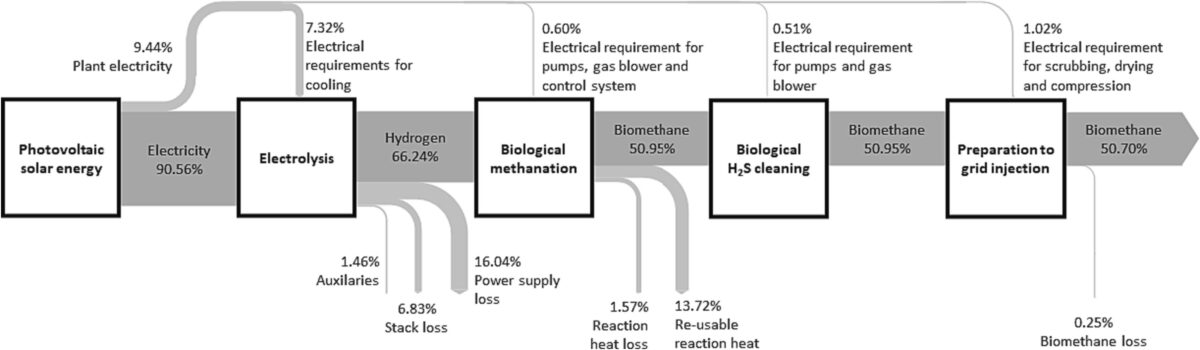

Proving that the discontinuous process is feasible, the scientists propose a techno-economical evaluation. They calculated the PV-driven biomethanation plant to use an average of 28 MWh of solar PV energy daily. The electricity load for the process was calculated at 2,675.59 kW, and 2,423.07 kW of it (or 90.56%) is used for H2 production via electrolysis.

“If a pre-commercial TBR biomethanation plant is deployed at an existing biogas facility, the biomethane levelized cost of biomethane production (LCOP) in a 2030 scenario is $147.84, with electrolysis as the most significant cost contributor,” they concluded. “Although this LCOP is higher than conventional biogas upgrading, biomethanation offers the possibility of CO2 capture and utilization.”

They presented the novel system configuration in “Sunshine-to-fuel: Demonstration of coupled photovoltaic-driven biomethanation operation, process, and techno-economical evaluation,” which was recently published in Energy Conversion and Management.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.