An international research team has proposed a novel photovoltaic-thermal (PVT) module design that purportedly reduces the risks of cracking in the panel's PV unit.

“A critical issue for PVT collectors is cell cracking, mainly caused by thermal expansion during the heat transfer process between PV cells and the thermal absorber,” the group explained. “Due to the high temperatures, these expansions and contractions create small silicon cell flaws, which may result in numerous micro fractures/cracks. These cracks may cause the disconnection of cell parts, resulting in a reduction in the overall power generated by the PV modules.”

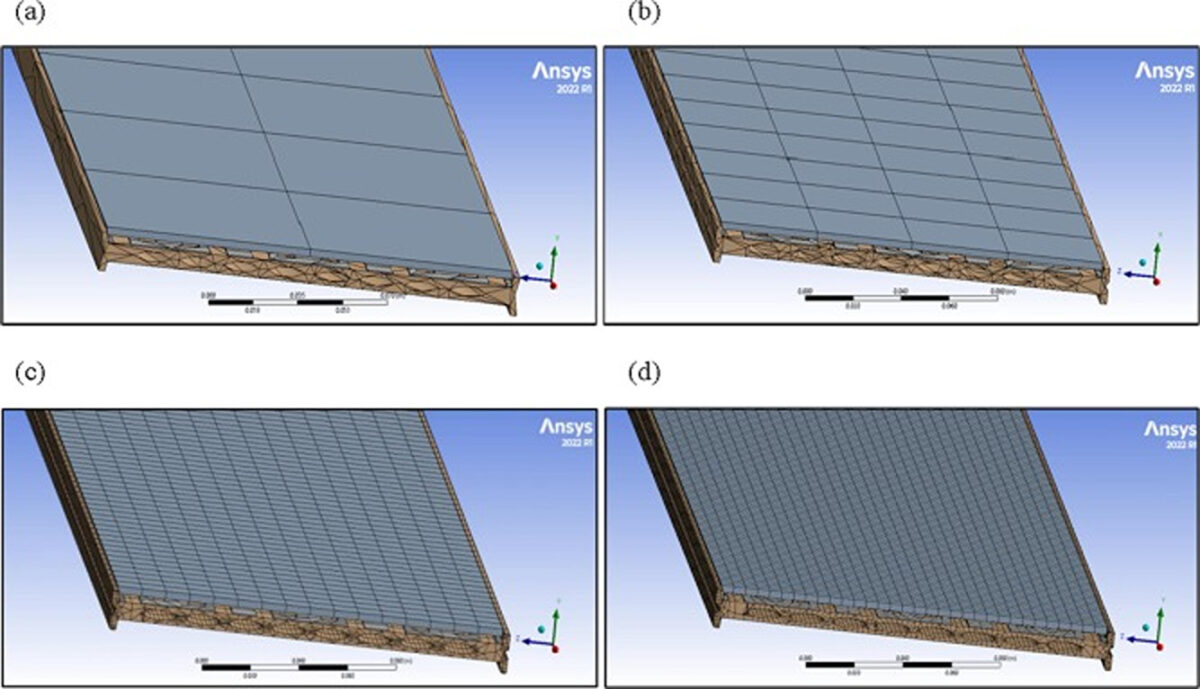

The scientists built a PVT module structure based on an aluminum alloy structure with an H-shaped pattern between the thermal absorber and the cells. Using the ANSYS software, they assembled a prototype based on a commercially available 44.2 W PVT module.

The new collector design was made up of the following components, from top to bottom: a transparent glass cover, a top ethylene vinyl acetate (EVA) layer, a PV panel made of monocrystalline silicon cells connected in series, a bottom EVA layer, an H-pattern plate for thermal expansion, a thermal absorber that transfers heat to the heat transfer fluid, and an insulation layer.

“One of the main goals of this design was to allow thermal expansion in all directions (by expanding into its cavities), thus creating a smaller total expansion in any single direction, which in turn was expected to diminish the risk of cell cracking drastically,” explained the academics.

The research group simulated the H-shaped aluminum alloy pattern to have seven different widths, from one mm to seven mm, in addition to a plate design without the structure. “It is evident that the directional expansion values are lower for H-pattern expansion cavity dimensions of 1, 2, 3, and 4 mm compared to the plate with no cavity (0 mm),” they explained. “Beyond 4 mm, a notable increase in expansion is observed for the H-pattern plate with a 5 mm cavity dimension. Additionally, the expansion values for cavity dimensions of 6 and 7 mm are slightly less than 5 mm, but all surpass the H-pattern plate with no cavity.”

Overall, the simulation found the optimal design to be the one with 2 mm H dimensions, as it exhibited the lowest directional expansion of about 0.011 mm. Compared to a simulation of a reference PVT, which was the same commercially available module but without the Hs, the novel one reduced thermal expansion by 20%.

According to the researchers, the novel design reached a 10% increase in thermal efficiency. Electric efficiency was increased by 2%, and overall efficiency increased by 8%. “This study provides valuable insights into PVT collector design, offering a promising solution to the challenge of cell cracking,” the scientists concluded.

The novel module design was presented in the study “Mitigating PV cell cracking in solar photovoltaic thermal collectors with a novel H-pattern absorber design,” published in Applied Thermal Engineering. The research group was formed by scientists from the UK’s Kingston University and Cranfield University and Sweeden’s MG Sustainable Engineering and University of Gavle.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.