A survey of 110 experts identified by the Transport and PV group at the International Energy Agency’s Photovoltaic Power Systems Programme (IEA-PVPS) Task 17 (T17) reveals a set of technical requirements or areas seen as important for the adoption of vehicle-integrated photovoltaics (VIPV) with a focus on passenger vehicles.

The study was conducted by the Netherlands Organisation for Applied Scientific Research (TNO) and includes experts' views on what users may be willing to give up in terms of PV yield to achieve superior vehicle aesthetics.

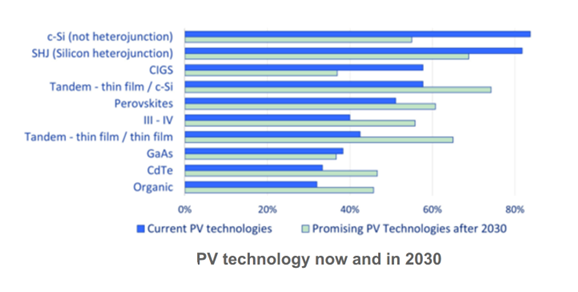

When it comes to the choice of cell technology for VIPV, crystalline silicon (c-Si) is dominant with a clear preference for back contact technology and no visible metal. However, by 2030 survey respondents expect tandem and thin film technology to grow.

“The desire for minimal visibility of metal on the front side of cells, coupled with a preference for glass on roof components and polymer on other surfaces, indicates a strong aesthetic consideration in VIPV design,” said the researchers.

The study considered the variety of cell technologies available in prototype and commercial VIPV passenger cars. For example, startups Lightyear and Sono Motors used c-Si, while Japanese automakers Toyota and Nissan used Sharp’s III-V compound solar technology, and Germany’s Flixbus and European joint venture Volvo-Renault have used CIGS

Several system features, including color, charging frequency, and cost, were ranked with the most important being efficiency, additional mileage per year, and vehicle range extension. “The report underscores the paramount importance of these factors, alongside the significant benefit of reducing the need for charging,” noted the researchers.

Looking at efficiency based on an available area of 3 m2 area, the respondents agreed on the minimum power conversion efficiency of at least 20% to 22%, with power output ranging from 600 W to 660 W, while a large group, 29%, said it should be greater than 25%, with power output reaching 750 W.

Module lifetime of at least 10 to 15 years was indicated, along with the need for repair concepts that include spot repairs for visible damage and full-body replacement parts for performance failures.

Popular content

The cost of VIPV systems, manufacturing and installation costs, are expected to fall by as much as 60% by 2030, according to the survey results. The largest technical bottleneck to lower costs is the complexity of manufacturing.

Asked about surprising results, TNO scientist and co-leader of the task group, Anna J. Carr, told pv magazine, “Probably the amount of performance that people were willing to sacrifice to get the colors they wanted. Among the respondents who said more color choice, than black or dark blue, is required an average performance loss of 24.2% was indicated to be acceptable.”

Around 62% of respondents came from PV research, while 13% came from PV cell or module manufacturing, 9% from automotive manufacturing, and 8% from automotive research. The majority are from Europe, with just 20% from Asia and a small percentage from North America.

“The reason that so many of the respondents were European is that the invitations to take part in the survey went out to the companies and researchers that we knew who were already working on the topic. And it represents the membership mix of T17,” said Carr.

Looking ahead, the researchers recommended adding more industry professionals to the survey group to be able to develop a better understanding of VIPV preferences and requirements. In addition, the group is likely to expand the focus and look at VIPV in heavy-duty and commercial vehicles, according to Carr.

The objective of Task 17 of the IEA PVPS is to deploy PV in the transport sector, contributing to reducing CO2 emissions of the sector and enhancing PV market expansions.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.