A research group from China’s Dalian University of Technology has investigated the hydrodynamic performance of a novel modular floating photovoltaic (FPV) system composed of interconnected buoyant units with articulated joints.

For the investigation, the team has developed a new hybrid approach, which integrates viscous-flow effects from computational fluid dynamics (CFD) into a potential-flow solver to enhance motion response predictions.

“Distinct from conventional floating barges, the proposed FPV module in this study is designed with an open central region, resulting in a ringlike geometry,” the team said. “Generally, open compartment floaters offer significant advantages over conventional solid box-type designs for ocean-based floating PV systems, particularly in harsh marine environments. Their semi-open structure enhances hydrodynamic performance by allowing water to flow through, reducing wave impact forces through turbulence and vortex shedding, while also damping resonant motions that destabilize PV panels.”

To evaluate the hydrodynamic behavior of this system, a hybrid numerical approach was used. First, the researchers used CFD, a method that solves the full flow of water and air. It was used to measure the damping coefficient, which represents the extent to which motion is reduced by viscous effects. Those damping coefficients are then transferred into a boundary element method (BEM), which is an efficient potential-flow solver. By using both, the novel method reportedly yields a solver that is both efficient and realistic.

“Comparative validation with CFD simulations and available experimental data confirmed the model’s capability to reliably predict the kinematic responses of both single and articulated multi-body floating systems under regular wave conditions,” the academics said. “Following this validation, a series of sensitivity analyses were conducted to examine the influence of two key parameters: the number of articulated floating modules and the geometric arrangement of those modules.”

Image: Dalian University of Technology, Applied Ocean Research, CC BY 4.0

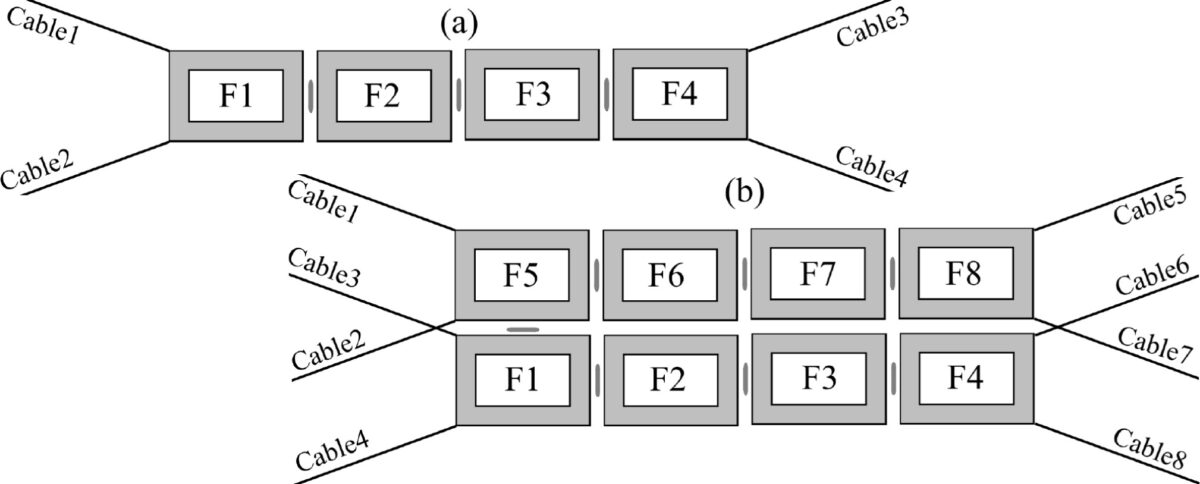

The simulation analyzed the arrangement of one to six FPV modules, either in a single-chain configuration or a parallel configuration, where two channels are placed side by side. For each configuration, the simulations were conducted across 12 regular wave frequencies. That was done to capture the hydrodynamic behavior under various conditions. According to the team’s findings, motion responses of articulated floats are essentially consistent across different configurations, with the most significant variations occurring near the natural frequencies of each degree of freedom.

“Increasing the number of interconnected floats generally reduces pitch motion and leads to diminishing differences in the dynamic response between adjacent modules, particularly beyond the second float,” they added. “Forces in the articulated joints tend to increase with wave frequency up to a peak and then decline, with mid-body articulations generally experiencing slightly higher loads than end connections.”

Concluding, the academics said that the parallel configuration exhibits slightly reduced motion amplitudes compared to the chain configuration. That, they say, indicates a damping effect when modules are added laterally, in addition to longitudinally.

The system was presented in “Hydrodynamic performance of floating solar arrays with articulated modules for optimal wave adaptation,” published in Applied Ocean Research. Researchers from China Construction Power and Environment Engineering, and Germany’s University of Duisburg–Essen have participated in the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.