A research team led by scientists from the United Arab Emirates’ (UAE) University of Sharjah has developed a novel model to optimize the cleaning schedule of PV panels in power plants located in deserts. They have demonstrated the technique using data from a 10 MW solar power plant in Masdar City, located in the Emirate of Abu Dhabi.

“Our approach aims to minimize both cleaning costs and financial losses resulting from power reduction due to soiling. The proposed methodology offers valuable insights for decision-makers in the UAE, enabling them to make informed decisions tailored to their specific priorities and constraints,” the scientists said. “Ultimately, this research seeks to enhance the performance of solar power plants in the UAE and support the advancement of sustainable and efficient energy systems.”

The novel technique uses a commercial optimization solver (CPLEX)-based mixed-integer programming (MIP) model. The CPLEX-based MIP model is fed with environmental data, including irradiance, temperature, and soiling rate; operational data, such as cleaning system parameters; and economic factors, including cost data. The model equations are then used to calculate the system’s energy output, soiling loss rate, and cleaning constraints. All of that is done considering the objective function of balancing energy loss cost against cleaning expenses.

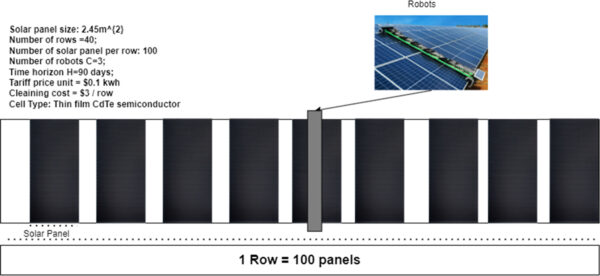

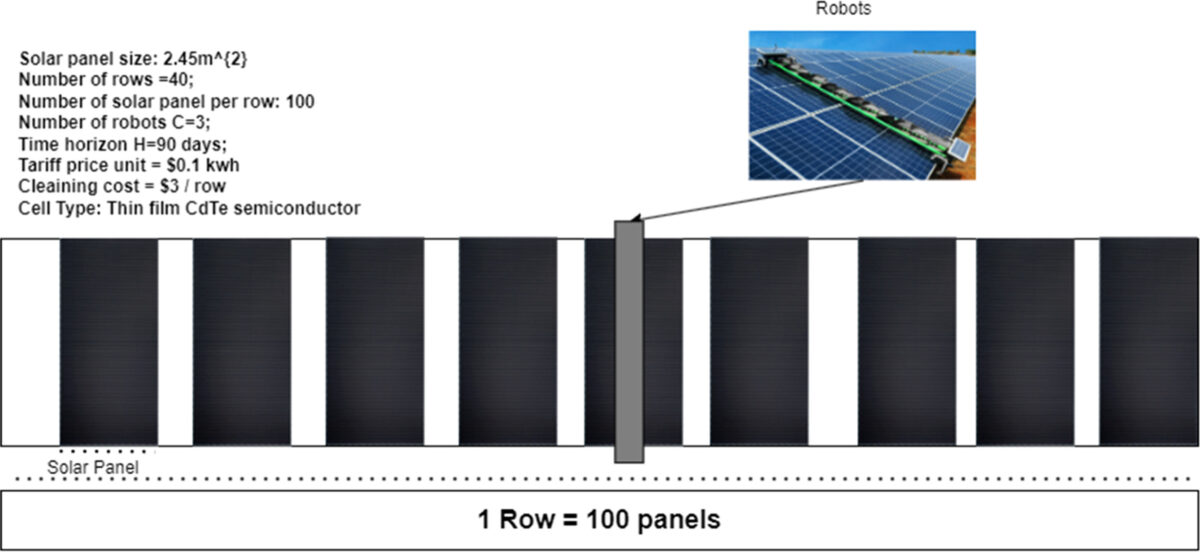

Image: Sustainable Futures, University of Sharjah, CC BY 4.0

To demonstrate the model, the team took the entire operational data of the Masdar City Solar Photovoltaic Plant from 2022. According to the collected points, the 10 MW park generates 17,564 MWh annually, from 87,780 PV modules. The facility area is 210,000 square meters, with 4,389 rows, each containing 20-100 panels. The soiling rate is considered to be 0.02% to 0.9% per day, and the energy tariff is $0.1/kWh.

Their simulation was conducted on a portion of the park, comprising 40 rows of 100 panels each. They assume the use of two robotic cleaners operates over a 90-day horizon, with cleaning intervals ranging from 3 to 20 days. The cleaning price was simulated at either $0.012 per square meter or $0.05 per square meter. The optimization model was then used to calculate when and which rows of panels should be cleaned over the three months.

Per the results, the cleaning process is optimized by cleaning three rows per day. The number of cleaned solar panels per row during the 90 days ranged from five to nine, with most rows being cleaned six or seven times. Cleaning costs totaled $4,833 when assuming a rate of $0.012 per square meter, and totaled $7,987 when the cleaning cost was $0.05 per square meter.

“By bridging quantitative optimization with practical considerations, the model offers a valuable decision-support tool for industry and policymakers,” the group concluded. “Limitations include an optimality gap of 21.65%, reliance on his tropical soiling data without real-time variability, and absence of empirical validation through tools like PVsyst or SCADA systems.”

Their work appeared in “Optimizing the cleaning plan of a solar PV system plant,” published in Sustainable Futures. Scientists from the University of Sharjah in the UAE, the University of Jean-Monnet in France, and the University of Tunis El Manar in Tunisia have participated in the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.