How to combine mechanized farming with agrivoltaics

An international study finds that successful agrivoltaic projects require farm-specific, holistic co-design that integrates PV layout with agricultural mechanization from the earliest planning stages. Without proper alignment between machinery, crops, and PV systems, agrivoltaics risk major land loss, lower field efficiency, and higher operating costs, undermining farm profitability.

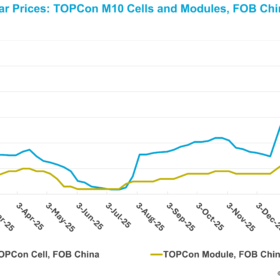

China TOPCon solar module prices ease after 4-week rally on silver pullback, holiday slowdown

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

Photovoltaics for salmon farms

Copec, Luxmeter Energy, and Ventisqueros have commissioned a system at the Quintupeu salmon farming center in Hornopirén, a remote area of southern Chile. The installation features a 48 kW photovoltaic plant paired with a 109 kWh battery storage system, enabling the facility to reduce its reliance on diesel generators in this off-grid aquaculture operation.

French railway operator tests solar on train tracks

Swiss startup Sun-Ways is testing removable solar panels installed on an operational railway line through a pilot project with French railway operator SNCF in Switzerland.

Hong Kong–based startup launches glass-fiber composite solar module frames

Xilia Group has introduced composite frames for solar modules made from glass fiber–reinforced polyurethane. The company says the frames reduce weight, resist corrosion, and eliminate the need for grounding.

Astronergy adopts quarter-cut cell design, boosting TOPCon module efficiency and reliability

The company’s new ASTRO N7 Pro PV modules achieve 2% higher cumulative energy yield over the project lifecycle compared to conventional previous-generation modules, according to Astronergy Head of Global Product Management Baohua He.

Vietnam more cost-competitive than India in cell, PV module production, says IRENA

IRENA’s latest report finds that energy use and material intensity across the solar PV manufacturing supply chain will decline through 2030. The analysis also shows Vietnam remains more cost-competitive than India due to lower electricity prices, while high energy and labour costs keep Australia and Germany less competitive.

The transition to back contact follows market trend toward long-term solar project sustainability

Module quality, reliability, and proven field performance are at the core of bankability assessments and investment decisions for solar PV projects, according to Chao Jia, President of LONGi Europe for DG. He says this is why advanced module technologies like back contact are gaining relevance.

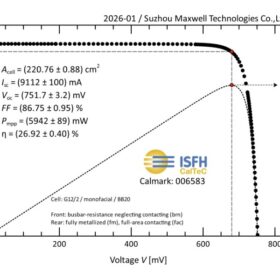

Maxwell claims 26.92% efficiency for heterojunction solar cell

The Chinese PV equipment provider said the result was certified by Germany’s Institute for Solar Energy Research in Hamelin (ISFH). The cell was fabricated with Maxwell’s in-house heterojunction production-line equipment and an end-to-end process flow.

New surface texturing boosts TOPCon solar cell efficiency by 1%

Chinese researchers have demonstrated a single-step submicron structured surface texturing process that improved the absolute efficiency of a TOPCon solar cell by 1% through broadband anti-reflection and lower electrical resistance. The cell-level performance was validated in laboratory and outdoor tests.