Solex Energy to open 2 GW TOPCon cell plant in 2027

India’s Solex Energy has started working on its new 2 GW n-type tunnel oxide passivated contact (TOPCon) solar cell factory, with operations set to begin in early 2027.

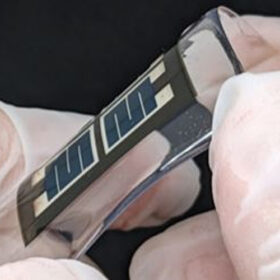

Japanese scientists build bendable perovskite-silicon tandem solar cell with 26.5% efficiency

The tandem device is based on a bottom thin-film heterojunction cell that can bend and a top perovskite cell that can be manufactured with a low-temperature process to prevent damage. It achieved the highest efficiency ever recorded to date for a flexible perovskite-silicon tandem solar cell.

DAS Solar plans 3 GW solar module factory in France

Chinese manufacturer Das Solar says it will open its first European PV panel assembly plant in Mandeure, eastern France, by the end of 2025.

Solar-air-ground CO2 heat pump system for renewables maximization

Researchers in Italy have designed a novel carbon dioxide heat pump that can work with photovoltaic-thermal energy, a finned coil heat exchanger and a U-tube borehole heat exchanger. Their experiment has shown that the simultaneous use of at least two energy sources always results in improved system performance even with limited heat transfer areas.

Aisin Corporation starts perovskite solar PV outdoor trial

The Japanese automotive components and systems manufacturer began testing its proprietary organic perovskite solar modules in what will be a 30 kW outdoor field trial at one of its facilities in Anjo.

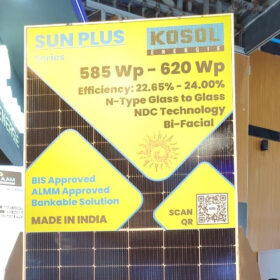

Kosol Energie launches TOPCon solar module with 24% efficiency

The Indian manufacturer said its new n-type TOPCon bifacial solar module has a a power output of 585 W to 620 W and the same compact dimensions as a traditional 550 W panel.

Japan’s Toyo begins production at 2 GW solar cell plant in Ethiopia

Toyo Co. has started production at its 2 GW solar cell facility in Ethiopia, with plans to deliver more than 80 MW of tunnel oxide passivated contact (TOPCon) cells by the end of April before scaling capacity to 4 GW.

Solar module prices unaffected by tariff chaos

Martin Schachinger, founder of pvXchange.com, says the European PV market has remained unaffected by the disruptive effects of the Trump administration’s new tariff policy.

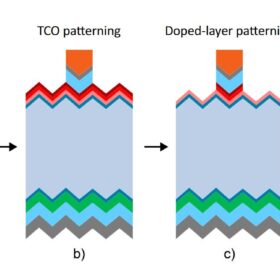

TU Delft researchers build 23.4%-efficient heterojunction solar cell with localized front contacts

Researchers at the Delft University of Technology have developed a top-down processing method localized the front contact in heterojunction solar cells. The new technique reportedly improves a cell’s short-circuit current density enabling higher power conversion efficiency.

Low-cost conductive quantum dot inks for photovoltaics

An international research team has developed a method to economically synthesize and stabilize conductive colloidal quantum dot inks for solar applications. When used to make quantum dot films in large area PV devices they enabled a certified efficiency of 10%, with lab-sized cells based on the ink material achieving 13.40% efficiency.