Technology Highlights 2018

The 2018 Technology Highlights feature counts down 25 of the year's top innovations in solar manufacturing. With huge new capacities ramping up across Asia, and module makers looking to differentiate their products, boosting volume and efficiency are the name of the game.

With this in mind, our jury of independent experts selected the following innovations as worthy of special recognition:

GTAT Polysilicon Tube Filaments

GTAT Polysilicon Tube Filaments

GT Advanced Technologies states that its Tube Filaments can increase annual polysilicon production rates in the Siemens process by more than 30%, whilst reducing energy consumption by 20%. The jury noted that this solution overcomes several issues in polysilicon production, and that it could become a new industry standard.

3D-Micromac Microcell OTF

3D-Micromac's dual lane laser processing system for silicon cells allows for double lane throughput, with both lanes working independently of each other. The innovation was singled out by the jury for its impressive throughput of 8,000 wafers per hour, with fewer laser heads per line and no contact transport.

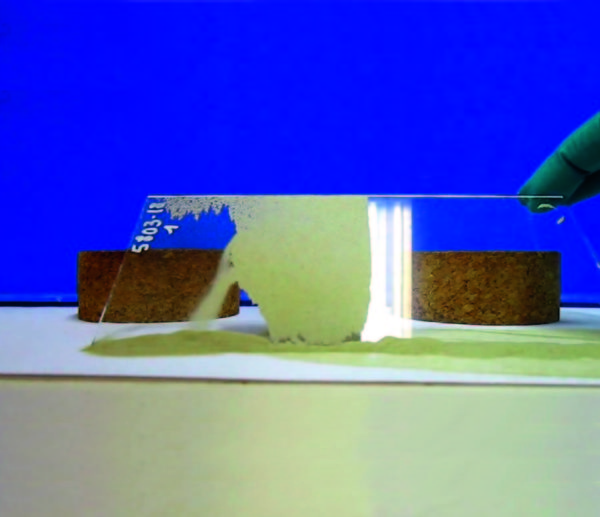

1366 Technologies Direct Wafer Process

1366 Technologies Direct Wafer Process

An innovation with truly transformative potential, the Direct Wafer Process was chosen as the 2018 Technology to Watch. 1366 says that its process could cut wafer costs in half and even lower, and also allows for further innovation in the wafer structue, such as extremely thin wafers to to minimize material consumption, with reinforcement in particular areas.

The full, 20 page feature, in which an expert jury selected by pv magazine ranks 25 of the top innovations in pv manufacturing is available here. Once again, thank you to all who participated!

Technology Highlights 2017

The feature’s third incarnation came at a time when diamond wire sawing had seemingly proved itself as an effective way to cut costs in wafer production, and manufacturers were well on the way to adopting mono PERC and even heterojunction production technology.

With this in mind, our expert jury selected the following joint winners:

Schmid DW PreTex Solution

Schmid DW PreTex Solution

The smooth surface left behind by DW sawing can create problems at later stages, especially in multicrystaline. Schmid’s DW Pretex solution addresses this, opening the way for cost effective diamond wire sawing in multi production.

“We are happy and honored to receive the award, it really confirms that we are on the right track,” says Christian Buchner, Vice President of the Photovoltaics Business Unit at Schmid. “With our solution we think we have hit the right spot with a simple, easy to use and inexpensive process, so that people can texture diamond wire-sawed multi wafers.”

MacDermid Enthone Helios PoSi Plating Process

MacDermid Enthone Helios PoSi Plating Process

Helios PoSi utilizes an innovative laser ablation process to expose silicon, then deposits nickel, copper, and a small amount of silver into the opening. The process could dramatically reduce the amount of costly silver required in cell metallization.

“MacDermid Enthone greatly appreciates the recognition from our PV industry colleagues as a 2017 Technology Highlights Award recipient,” states Bruce Lee, Global Applications Manager for Photovoltaics at MacDermid Enthone. “We hope our investment in developing this novel metallization process will enable low cost expansion of the PV industry worldwide.”

Alongside these two winners, our jury also decided to recognize an additional development as the ‘Technology to Watch' for 2017.

Sinton Instruments FCT-750 Cell Tester

Sinton Instruments is bringing R&D level analysis to production lines. The FCT-750 enables advanced optimization of cells and modules, with measurements such as true series resistance and direct shunt.

“This recognition of our technology aligns with our mission and validates our goal. Changing the way things have always been done is not easy,” says Ron Sinton, founder and president at Sinton Instruments. “A comprehensive analysis at cell test can allow quick innovations on the production line to bring new processes up and precisely target problems before they can cause significant loss.”

The full feature for 2017, which counts down 30 of the finest new PV manufacturing technologies, is included in the April edition of our magazine, and can also be viewed here. We would like to thank all who entered for sharing their time and expertise with us. As our jury member Andrew Blakers of the Australian National University puts it: “One thing that comes out of being involved in awards like this is to see that there is no end in sight to the cost reductions possible in a silicon solar cell.“

Technology Highlights 2016

Technology Highlights 2016

2016's Technology Highlights feature and award also arrived a vital time for the industry, as cost pressures drove innovation in manufacturing processes from ingot all the way to module.

In this year, the jury selected these technological advances as the most worthy of recognition:

Meyer Burger DW288 Diamond Wire Solution

Meyer Burger DW288 Diamond Wire Solution

Meyer Burger's DW288 Series 3 diamond wire saw is designed to reduce kerf, using the thinnest wires possible, and increase wire life by preventing wire to wire contact.

“The product development team at Meyer Burger was very pleased to have their DW288 Series 3 saw, which has now been very successfully launched in the PV market, recognized with such a prestigious award,” said CIO Dirk Habermann. “Being selected by a jury of solar industry experts was an honor which clearly confirmed our continued determination to further advance photovoltaic technologies.”

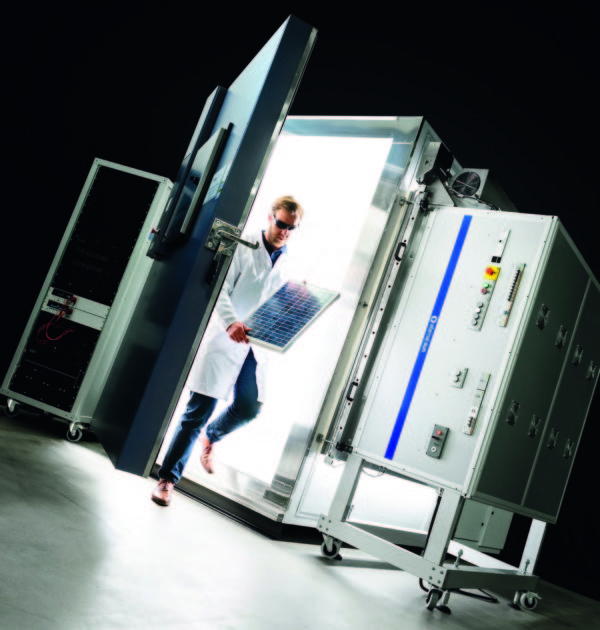

Eternal Sun climate chamber/sun simulator

Eternal Sun climate chamber/sun simulator

Combining a climate chamber and solar simulator, Eternal Sun's technology allows simultaneous solar and environmental degradation testing. The chamber can conduct I-V curve measurements under a range of conditions.

“Winning the award symbolized the recognition of the industry for our technology and our company,” said Florian van Rijn van Alkemade, CEO at Eternal Sun. “Being a part of Technology Highlights proves to us that we are working on equipment and services that are innovative and leading, and shows us that we are on the right track.”

For the first time, in 2016 the jury also decided to give the ‘Technology to Watch award, for a development at an earlier stage which shows great potential.

DSM Anti Soiling Coating

DSM Anti Soiling Coating

The Netherlands' DSM is recognized for creating a new solution to the problem of soiling, particularly relevant as more dry and dusty regions begin to realize their potential for solar deployment.

Technology Highlights 2016 also features a rundown of the year's top 30 innovations in manufacturing, as included in the May 2016 issue of pv magazine. The full feature counting down all 38 entries is available here.