A consortium formed by 11 companies and five research institutes from nine EU countries has published the results of a project that demonstrates the end-of-life management and recycling of PV modules is highly economical.

In the Horizon 2020 CABRISS project, launched in July 2015, the consortium’s researchers demonstrated three main techniques can be used to extract “high-value, high-yield” reusable materials from recycled panels: a process for delaminating and recovering high-value materials including silver, indium, silicon and high-purity glass from PV end-of-life thin film and Si-based PV modules; a technique for the recovery of solid waste from solar manufacturing – a mix of broken Si wafers and cells; and a kerf process to dry silicon powder PV production waste from material lost during the cutting process.

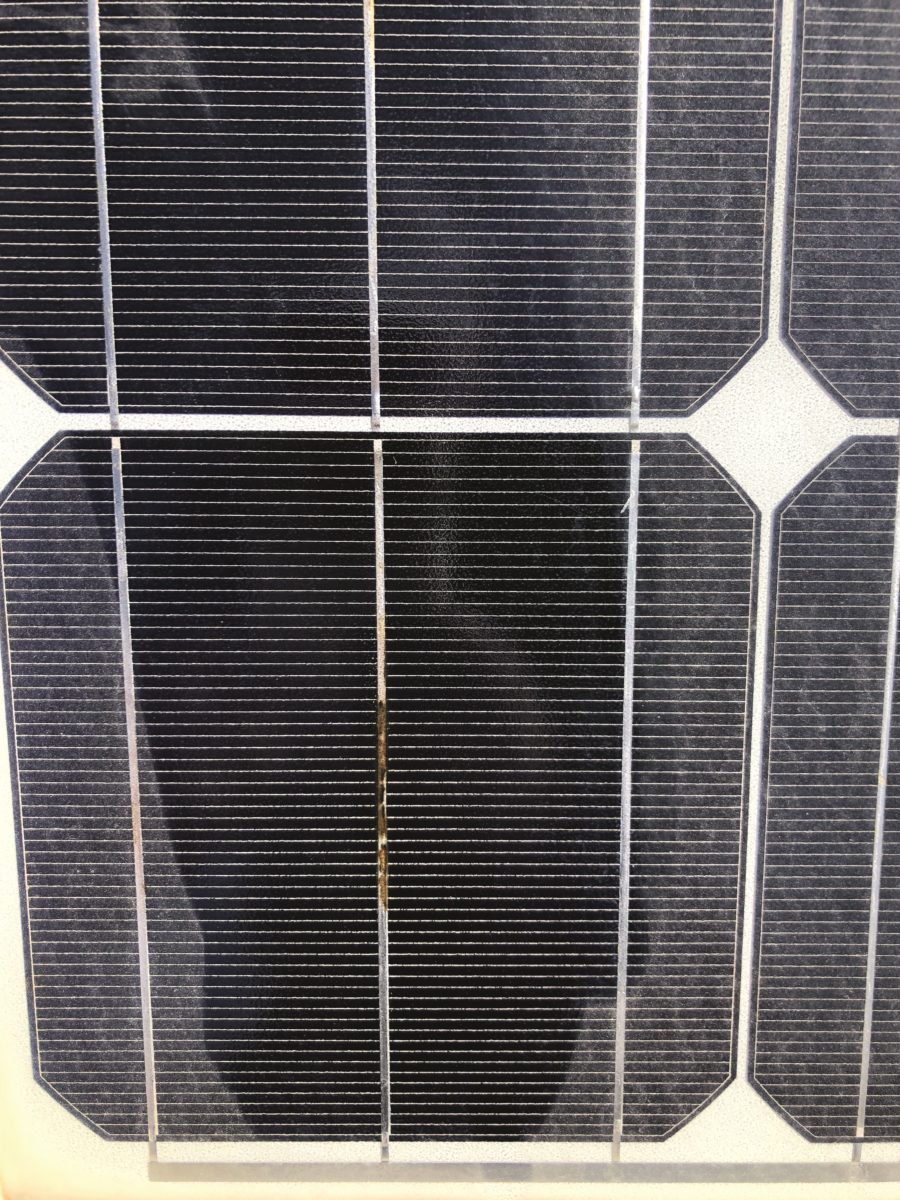

To open modules without damaging them, the researchers used a laser technology said to increase the value of the recovered glass. “For Si-based PV modules, an innovative and water-based technology was developed which, unlike conventional shredding technologies, does not break glass, resulting in the collection of all materials in Si PV modules,” said project coordinator, David Pelletier.

The project developers point out the EU’s Waste Electrical and Electronic Equipment (WEEE) directive – which came into force in February 2014 –stipulates that by this year at least 85% of waste from PV modules must be recovered, and 80% of it recycled or reused.

PV panel waste could become $15bn market

The WEEE also requires panel producers that supply modules to the EU market to finance the collection and recycling of their end-of-life PV panels.

Popular content

“The result is WEEE-compliant recycling of PV wastes, increasing [the] yield and quality of recovered materials, including silicon, indium, silver, and high-quality undamaged glass,” Pelletier said.

The researchers have also developed techniques for the reuse of silver and silicon embedded in panels. They purified the recovered silicon from broken wafers and cells to solar-grade (5N) material by pyro and hydro-metallurgical processes for direct reuse in the PV industry.

According to a report released by the International Renewable Energy Agency (IRENA) in 2015, PV panel waste volumes in 2050 could be worth $15 billion on global commodity markets, provided proper recycling and repurposing of materials is carried out.

According to projections by IRENA and the International Energy Agency's Photovoltaic Power Systems program (IEA-PVPS), global installed PV capacity could rise to 4.5 TW by 2050. If PV panel waste by that date was fully injected back into the economy, solar could boast one of the most robust “closed-loop” business models in existence.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Its indeed a wonderful attempt. The economics of recovery cost of the materials need to be mentioned to make it more lucrative.

Some of the African country are looking for local manufacturing of the small solar system would that be an opportunity to receive solar cell