EV sales passed 10 million last year and the International Energy Agency predicts 40 million in 2030. Growth is underpinned by battery manufacturers striving to keep pace with demands for enhanced performance and range. Such growth is driving a pressing waste challenge.

After 10 years to 15 years, EV batteries retain 70% to 80% of their original capacity, rendering them unsuitable for further automotive use, according to Dutch EV equipment supplier EVBox. The International Council on Clean Transportation estimates, by 2040, some 14 million EV battery packs will reach end-of-life annually. There is an urgent need for safe, responsible end-of-life battery management.

After 10 years to 15 years, EV batteries retain 70% to 80% of their original capacity, rendering them unsuitable for further automotive use, according to Dutch EV equipment supplier EVBox. The International Council on Clean Transportation estimates, by 2040, some 14 million EV battery packs will reach end-of-life annually. There is an urgent need for safe, responsible end-of-life battery management.

Research has focused on recycling batteries, to recover valuable materials including cobalt and lithium, with 35 EU recycling projects active or due by 2025. Less attention has been paid to preserving the inherent value of batteries. The concept of giving devices a second, or even third life, is gaining traction as it maximizes utilization of materials and energy and postpones recycling for years, or even decades.

Recirculate is a project funded by the EU’s Horizon Europe research program and Swiss federal body the State Secretariat for Education, Research and Innovation. The initiative is pioneering a “4R” approach for batteries, encouraging repair, reuse, and remanufacture, before recycling. It will revolutionize the battery sector by developing the technologies and systems to enable cascading reuse of batteries in second-life applications such as battery energy storage systems. Led by Finland’s Centria University of Applied Sciences, Recirculate brings together research and industrial partners from eight countries, including the Ford Otomotive Sanayi carmaker owned by Ford and Turkish conglomerate Koç Holding, and DHL.

Barriers to reuse

The first major hurdle to giving batteries a second-life is understanding their type and condition. EV battery packs comprise thousands of cells organized into modules and do not feature standard labelling. For optimal performance, second-life batteries must use cells with matching electrode chemistry and condition, creating a need for data on battery cell type and parameters such as state of charge, remaining useful life, state of health, and state of safety – collectively known as “state of x” (SoX). Battery management systems hold some of this data at pack level but original equipment manufacturers do not typically provide this information. Obtaining cell-level SoX data requires time-consuming, costly, unreliable analytical methods. Recirculate is developing diagnostic tools and processes to accelerate characterization of battery SoX at pack, module, cell, and other levels.

A lack of safe, rapid, scalable battery pack dismantling – to enable module and cell reuse – is another barrier. There are hundreds of battery designs with variations in size, electrode chemistry, and form factors. The need to plan for every possible pack, module, and cell permutation makes robotic disassembly impractical. Robotic systems also struggle with damaged or non-conforming batteries. Manual dismantling is the norm but is slow, expensive, and dangerous; fully discharging a battery causes irreversible damage, preventing further use, so operators work on live batteries, exposing them to potential electrical, fire, and chemical hazards. Recirculate aims to revolutionize battery dismantling with artificial intelligence-based control systems to adapt to different battery designs and conditions, providing a faster, safer, and more cost-effective alternative to manual disassembly.

The storage and transportation of used batteries also poses challenges, due to the risk of thermal runaway and fire. Europe classes EV batteries as dangerous goods, in part due to their susceptibility to thermal runaway when subjected to impact or damage. Complying with regulations on storage and transport creates a safety and cost barrier to transporting used batteries across the EU, impeding second-life adoption. Recirculate is developing a cost-effective, intelligent, safe transport and storage system for battery packs, modules, and cells. Integrating temperature sensors and fire suppression into battery travel cases, the system will enable early detection of thermal runaway risk and the development of effective fire mitigation and prevention strategies.

Supply chain

Although the technical challenges above are significant, the biggest barrier to the adoption of used batteries is the fragmented state of the second-life battery supply chain. Manufacturers must build and maintain business-to-business supplier relationships, which restricts supply of used products and impedes the sourcing of battery modules and cells of the same SoX for reuse.

Popular content

Ideally, second-life battery manufacturers should be able to source used-battery components on the open market. However, a lack of transparent and trustworthy data on the type and condition of devices inhibits trade, increasing costs for battery remanufacturers as they must rigorously assess and characterize all modules and cells before deciding how to use them.

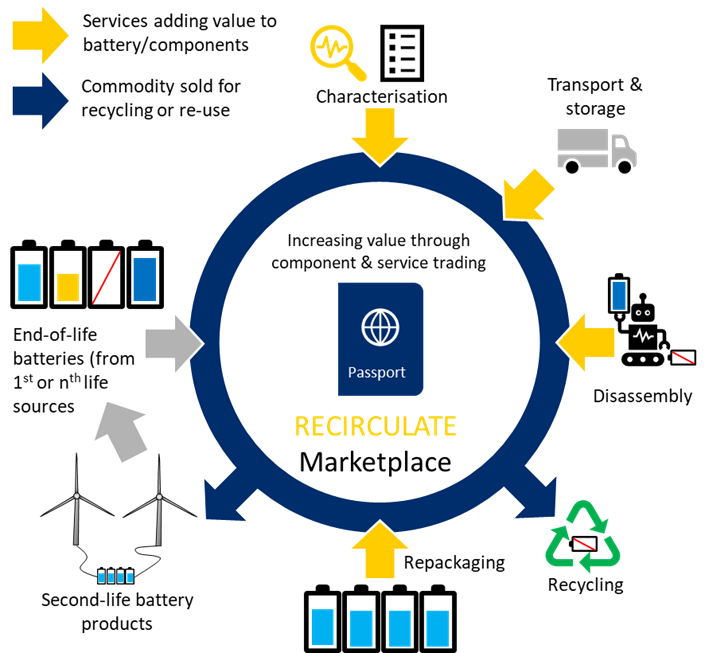

Recirculate will address this issue by developing, blockchain-backed product passports, holding a tamper-proof record of information on batteries and their components. This will provide supply chain actors with the trusted information they need to make informed decisions on how best to source and process used batteries. The program will establish a third-party marketplace underpinned by blockchain product passports, empowering consumers and commercial actors to source batteries of a specific type and condition with confidence.

A new model

The EU-Swiss initiative envisions an independent marketplace to create new business opportunities throughout the battery value chain. By expanding the supply of second-life batteries and their components and supplying a platform for services related to battery characterization, storage, transport, dismantling, remanufacturing, and trading, Recirculate aims to reshape the industry according to the needs of industry, consumers, and the market.

Recirculate consortium members will engage across the battery value chain to understand the challenges they face. This collaboration will ensure the project's competitive solutions align with the requirements of all interested parties, positioning European industry at the centre of a more sustainable battery value chain.

The Recirculate program will be delivered by Centria and compatriot automation and robotics company Probot Oy; Norwegian battery management business Eco Stor AS; Berlin-based supply chain traceability specialist Minespider Germany GmbH; Swiss battery-as-a-service provider Libattion GmbH and compatriot not-for-profit research entity the Centre Suisse D'electronique Et De Microtechnique Sa; Turkey-based DHL Lojistik Hizmetleri AS; Ford Otomotiv Sanayi; Ireland’s Iconiq Innovation Ltd; Spanish research and technology outfit Fundacio Eurecat; and Sweden’s Dafo Vehicle Fire Protection AB.

About the author: Dr Stephen Rippington is science communicator and innovation management consultant for Iconiq Innovation, supporting companies to develop circular and sustainable solutions. He has secured grant funding for EU and UK research and development projects across a range of sectors and has more than 20 years’ experience of planning and delivering complex, multi-disciplinary applied research projects for academia and industry.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.