A research team from Switzerland's Paul Scherrer Institute (PSI) has developed a new approach to improve the stability and lifetime of all-solid-state batteries (ASSBs). The work focuses on the argyrodite-type solid electrolyte Li₆PS₅Cl (LPSCl), which is widely considered one of the most promising materials for sulphide-based solid-state batteries.

The researchers combined a new sintering technique with the application of an ultrathin passivation layer to both densify the electrolyte and stabilise the interface with lithium metal.

“We combined two approaches that, together, both densify the electrolyte and stabilise the interface with the lithium,” corresponding author Mario El Kazzi said in a statement. “Our approach is a practical solution for the industrial production of argyrodite-based all-solid-state batteries. With a few more adjustments, it could be ready for manufacturing.”

According to lead author Jinsong Zhang, the optimised battery cell demonstrated strong electrochemical performance. In testing, the cell retained around 75% of its initial capacity after 1,500 charge–discharge cycles. “Its cycle stability at high voltage was remarkable,” Zhang said. “These values are among the best reported to date.”

LPSCl is a sulphide-based solid electrolyte composed of lithium, phosphorus and sulphur. Despite its high ionic conductivity, its commercial development has been limited by the difficulty of achieving sufficient densification to prevent the formation of voids that can be penetrated by lithium dendrites.

Previous studies relied on either very high pressure at room temperature or a combination of pressure and temperatures above 400 C to densify the material. However, these methods often resulted in a porous microstructure, excessive grain growth and degradation of the solid electrolyte, undermining battery performance and stability.

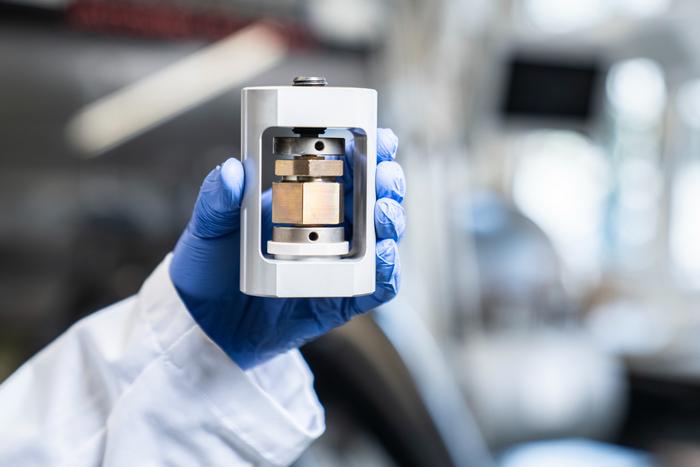

Image: Paul Scherrer Institute PSI, Advanced Science, CC BY 4.0

To address these challenges, the team developed a low-temperature, low-pressure sintering process. The LPSCl powder was first uniaxially pressed at 380 MPa at room temperature inside a glovebox. The resulting cold-pressed pellets were then transferred, under vacuum, to a chamber connected to the glovebox and pressed at 50 MPa for six hours at temperatures of 60 C, 80 C and 100 C.

Sintering at 80 °C was found to be optimal, improving surface uniformity and densification of the LPSCl pellets while reducing porosity and increasing ionic conductivity.

In a second step, ultrathin lithium fluoride (LiF) layers were deposited on 50 µm-thick lithium metal foils at room temperature using electron-beam evaporation. The LiF coating serves two functions: it suppresses electrochemical decomposition of the solid electrolyte when in contact with lithium and acts as a physical barrier against lithium dendrite penetration.

The researchers evaluated LiF thicknesses of 40 nm, 65 nm, 100 nm and 130 nm. A thickness of 65 nm proved optimal, providing uniform coverage that improved interfacial contact and stabilised formation of the solid-electrolyte interphase (SEI).

“This dual modification doubles the critical current density of lithium symmetric cells from 1.1 mA cm⁻² to 2.2 mA cm⁻²,” the researchers said. “In full cells with LiNi₀.₈Co₀.₁Mn₀.₁O₂ (NCM811) cathodes, stable cycling was achieved for more than 2,700 cycles at 1 mA cm⁻² and 1.5 mAh cm⁻², with 75% of capacity retained after 1,500 cycles.”

The system was presented in “Synergistic Effects of Solid Electrolyte Mild Sintering and Lithium Surface Passivation for Enhanced Lithium Metal Cycling in All-Solid-State Batteries,” published in Advanced Science.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.