An international group of researchers led by scientists from China’s Chongqing University has developed and thermodynamically assessed a novel compressed air energy storage (CAES) system that utilizes the roadways of abandoned coal mines for underground storage.

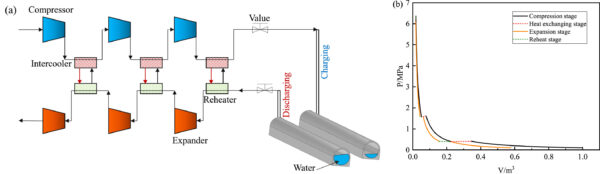

Called Flooded coal mine roadway compressed air energy storage (FM-CAES), the system accumulates energy during the day and releases it at night. When daytime electricity supply is abundant, excess power from wind and solar sources drives a multi-stage process that compresses air. This compressed air is then stored in abandoned coal-mine tunnels. At the same time, the heat produced during compression is captured by intercoolers and transferred to a thermal storage tank. At night, the stored air is reheated and expanded through a turbine to produce electricity. The retained thermal energy is used to warm the air during this discharge process, while the thermal storage medium cools back down to ambient temperature.

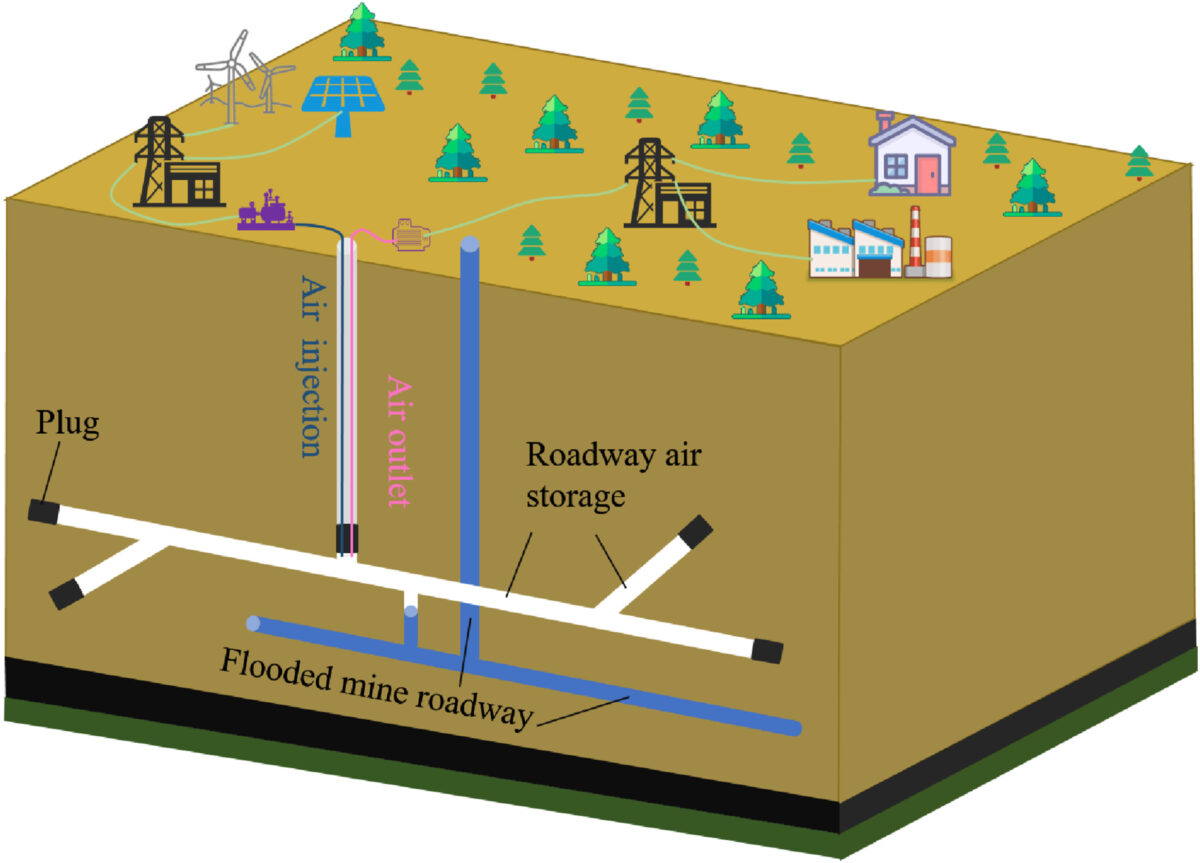

The system consists of three phases: in the charging phase, the cooled compressed air enters the air storage roadway through the air injection channel. As air enters, the water level in the roadway gradually decreases, and the displaced water flows into other deeper roadways. In the air storage phase, the compressed, high-pressure air is held at a constant pressure by the combined action of the geological formations and the hydrostatic pressure of the surrounding water. In the final, discharge phase, the air outlet channel is opened, allowing the compressed air to be released. The hydrostatic pressure of the water maintains a near-constant air pressure, minimizing fluctuations during discharge.

The FM-CAES system also uses water pressure to maintain constant air pressure, attempting to improve efficiency and reduce leakage. It operates with charge and discharge periods of 8 hours each, with compressed air storage and water flooding lasting 4 hours. In the COMSOL 6.0 software simulation, the ambient temperature was 292.65 K, the air mass flow rate was 26.91 kg/s, and the air was sourced at 6.2 MPa. The rated discharge power was 10 MW. Roadways had a radius of 2.1 m, with a lining thickness of 0.3 m.

Image: Chongqing University, Energy, CC BY 4.0

Through the simulations, the scientists found that the thermal efficiency of the FM-CAES system can reach 71.5%, with an energy storage density (ESD) of 29.72 MJ/m3. They also found that the system’s efficiency remained stable and was “largely” unaffected by the air mass flow rate. “Increasing the water pressure within the roadway from 4 MPa to 12 MPa resulted in a 38.2% extension in the storage time and a 27.6% reduction in air flow rate, accompanied by a slight improvement in system efficiency,” they emphasized.

The analysis also showed that effective air confinement was achieved with low-permeability surrounding rock and lining. For the surrounding rock, a critical permeability threshold of 1 × 10⁻¹⁷ m² was identified, below which the air leakage variation was minimal. For concrete lining, permeability below 1 × 10⁻¹⁹ m² effectively stabilized system efficiency. Deeper roadways exhibited a higher average air leakage rate (AALR) and ESD, though after a 30-year simulation period, the system efficiency was consistent across depths. This indicates that the impact of leakage rates on efficiency approaches saturation over the long term.

“The ESD increased more rapidly with depth, improving from 4.3 MJ/m3 to 6.7 MJ/ m3 for every additional 100 m of burial depth,” the academics concluded. “The exergy destruction of the system primarily occurred during the compression and expansion phases, accounting for exergy losses of 9% and 10.5%, respectively. Other phases incurred exergy losses below 4.3%.”

The system was presented in “Exploring compressed air energy storage in abandoned flooded coal mine: Thermodynamic analysis and applicability study,” published in Energy. Researchers from China’s Chongqing University, Sweden’s Luleå University of Technology, and the French National Centre for Scientific Research have participated in the study.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.