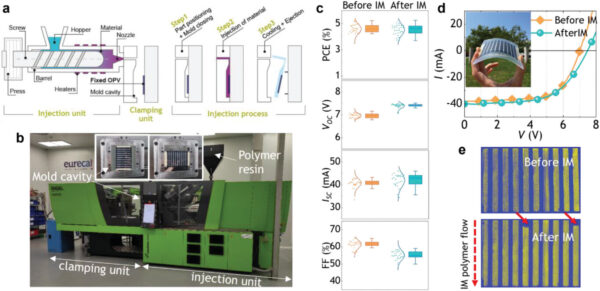

European researchers claim to have successfully demonstrated the embedment of organic PV (OPV) modules into structural plastic parts via large-scale industrial injection molding (IM).

IM is a manufacturing technique for producing parts by injecting molten material into a mold and has the ability, according to the research group, to enable the development of in-mold plastic solar cells with improved performance and stability.

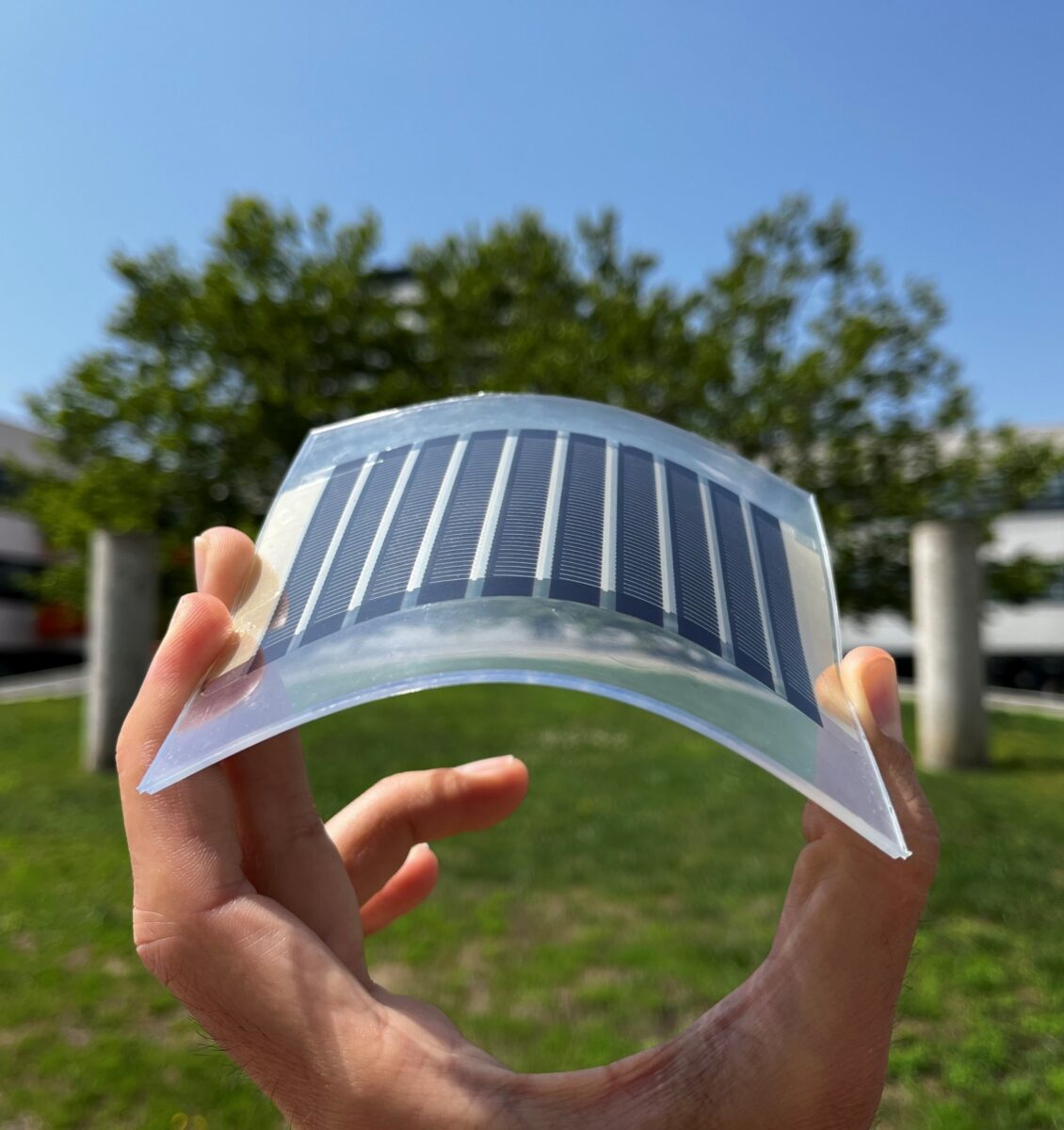

“Due to their very thin layout, flexible solar cells can be sensitive to mechanical abrasiveness and, therefore, might require additional protection and integration strategies,” the research group explained. “Embedding a printed solar module into a plastic part simplifies integration challenges, while providing additional mechanical protection, shape adaptability, and streamlined contacts for connections.”

The researchers first created modules in roll-to-roll printing, using a photoactive blend known as P3HT:O-IDTBR. This blend was chosen due to its morphological and thermal stability, which are relevant to the later injection molding process.

“OPV product development demands photovoltaic materials with high morphological stability under thermal stress, such as the P3HT:O-IDTBR blend,” the academics emphasize. “In that respect, higher performing materials with such stability are urgently needed.”

Image: EURECAT, Technology Centre of Catalonia, Advanced Science, CC BY 4.0 DEED

The scientists inserted the modules horizontally into an injection mold of polyether copolymer-based thermoplastic polyurethane. This material was chosen due to its low process temperature, broad substrate compatibility, and flexibility. The injection was done using a 120 mm × 120 mm × 2 mm cavity insert, at a 90 mm −1s speed.

“From the selection of 64 roll-to-roll printed modules, 32 of them were injected, and the other 32 modules were kept as references,” the researchers explained. “On average, the IM-OPV modules retained 98.1 of the original performance. Only 2 samples failed, and 28 samples preserved over 90% of the original performance, which sets the yield of the IM process close to 90%.”

As for mechanical and operational stability, the scientists found an average of more than 35% increase in the maximum stress point in the IM-OPV samples. The first fracture on the control devices occurred at 10–30% of strain, whereas this value jumped up to 70–150% on the IM-OPV modules. In addition, a power conversion efficiency retention of more than 90% was found after 50,000 cycles in the molded modules.

“This work represents the first demonstration of in-mold plastic solar cells and opens new possibilities for organic photovoltaics to enable specific applications that require simultaneous high optoelectronic and structural performances,” the researchers said. “We believe that future focus on injection plastic materials could further extend the benefits of in-mold photovoltaics in regards to structural and device stability, or even providing additional optical functionalities.”

Their findings were introduced in the paper “Injection Molding Plastic Solar Cells,” published in Advanced Science. The researchers come from the Eurecat Technology Centre of Catalonia, the University of Pardubice and the Centre for Organic Chemistry in the Czech Republic, as well as from French nano-metal producer GenesInk and Spanish injection molding provider Aitiip.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.