A new generation of organic PV and perovskite solar cell developers are making gains in efficiency and stability and taking steps closer to industrialization, according to more than two dozen presenters at the “Future of photovoltaics: organic, perovskites, CIGS, tandem” event in late January. The conference was hosted by Germany-based TechBlick, which specializes in online and live events about emerging technologies.

Looking back on the first day's sessions, TechBlick CEO, Khasha Ghaffarzadeh observed that organic PV (OPV) and perovskite solar cell manufacturers are adopting roll-to-roll (R2R) processing which he posited could be a new opportunity for the European PV manufacturing industry. “OPV and perovskite manufacturing, especially with R2R production, could offer Europe a route back to redevelop a solar cell production ecosystem,” Ghaffarzadeh told pv magazine.

Several companies from Canada and the United States took part in the event. “The perovskite production landscape seems very active in North America, with many manufacturing start-ups,” said Ghaffarzadeh.

Some of the companies in this group are Solaires, a Canadian perovskite startup that began as a perovskite ink supplier, and compatriot Brilliant Matters, which has developed a range of OPV materials. Both companies presented details about their progress. Solaires now has a pilot line to manufacture indoor PV modules, while Brilliant Matters is adopting a specialty chemicals business model to increase its production capacity.

U.S.-based perovskite solar startup Perotech, presented the latest highlights of its flexible PV technology, while materials specialist American Perovskites discussed licensing, scaling, and market opportunities.

From Europe, Greek startup OET described building its organic PV factory to produce specialty modules for various integrated PV applications in the automotive and building industries.

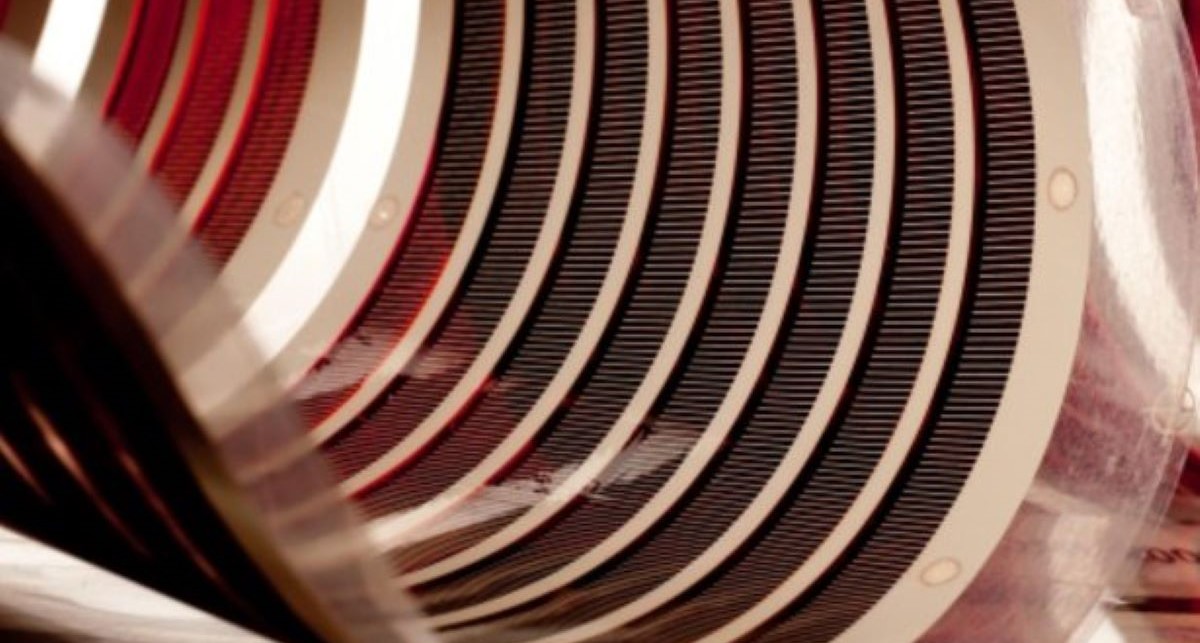

Italian startup Ribes Tech, which emerged from a collaboration between Italy’s OMET Group and the Italian Institute of Technology in Milan, is also establishing a production facility for R2R manufacturing of flexible OPV cells, initially to address the demand for indoor solar cells in wearable sensors and other electronic devices.

Startups from beyond North America and Europe described technology roadmaps, namely Australian startup Halocell, which is developing flexible perovskite cells and modules made with an R2R process, and Taiwan Perovskite Solar Corp, based in Zhubei City, Taiwan, which is working with industrial partners to make large area devices.

Equipment suppliers

Stability, scalability, and sustainability of newer PV technologies are only possible with appropriate manufacturing equipment and a reliable supply of materials. German company Coatema Coating Machinery presented its R2R processing solutions for OPV and dye sensitized solar cells (DSSC). It claims products to scale up from benchtop to pilot to full-scale fabrication.

Compatriot company Panacol was on hand too, presenting adhesives enabling structural and conductive bonding of foil laminates in flexible perovskite and OPV devices.

Another material supplier that generated interest at the event was Sweden’s n-ink, a developer of polymer conductor materials. It has a solution to enhance OPV performance, as well as other semiconductor devices. It is working on increasing its production volume. Some of n-ink’s products are already available on the Sigma-Aldrich lab and material platform.

Portugal startup Pixel Voltaic, a spinoff of University of Porto, presented its laser equipment that forms high-quality hermetic glass encapsulation of perovskite and other emerging PV devices.

These are just some of the 16 companies that presented over the two-day event, in addition to the representatives from seven leading research groups from China, the United Kingdom, North America, Saudi Arabia, and Germany.

Distilling the sessions to just a few words, it was apparent in every category, be it OPV or perovskite or others, that progress on the path to commercialization is being made. This is true whether progress is measured in terms of efficiency, stability, availability of specialized manufacturing equipment development, multiple sources of materials, or number of pilot lines. Some of the speakers made impromptu recruiting pitches from the podium to fill open positions. Business models are being financed, teams are being built, and research projects are ongoing.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.