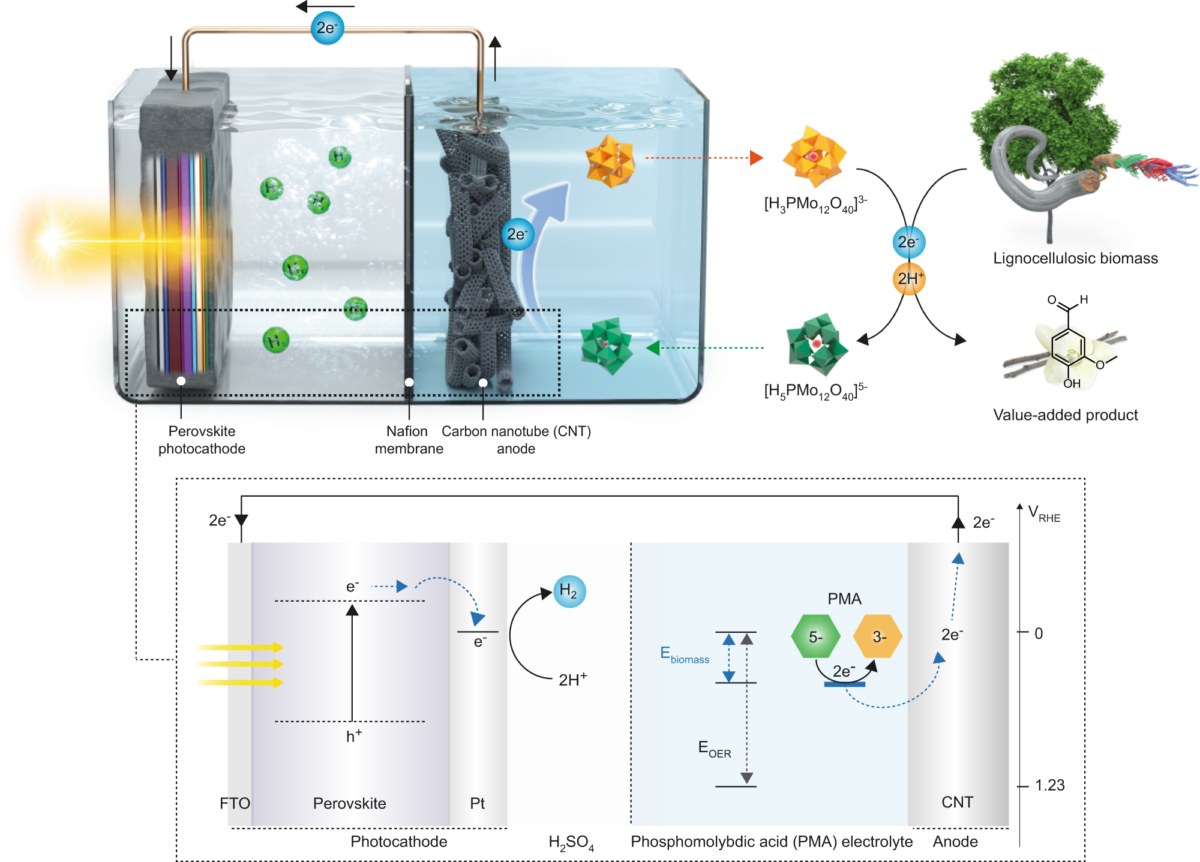

Ulsan National Institute of Science and Technology researchers in South Korea have presented a photoelectrochemical (PEC) cell with a record photocurrent density of 19.8 mA cm−2 for hydrogen production. It used a Nafion membrane and a high-performance, organic-inorganic halide perovskite as a panchromatic absorber. Instead of water, the team resorted to lignocellulosic (LC) biomass as an alternative source of electrons working at lower potentials. Water as a source of electrons is complicated, as water oxidation is the slowest process in solar hydrogen production, requiring a high potential. “LC biomass has been less explored, especially for solar hydrogen production, due to their low solubility and molecular complexity, which result in low conversion yields of LC biomass with poor selectivity,” the team wrote in “Bias-free solar hydrogen production at 19.8 mA cm−2 using perovskite photocathode and lignocellulosic biomass.” Value-added chemicals such as vanillin and acetovanillone are produced via the selective depolymerization of lignin in lignocellulosic biomass. At the same time, cellulose remains close to intact for further utilization, the researchers reported in the article published in Nature Communications.

Mitsubishi Heavy Industries (MHI) is building Takasago Hydrogen Park, the world's first center to validate hydrogen-related technologies. It will be dedicated to verifying hydrogen production, storage, power generation, and other next-generation technologies. “Hydrogen will be produced on-site using water electrolysis, and potentially also using other next-generation technologies such as methane pyrolysis to produce ‘turquoise' hydrogen with solid carbon as a by-product,” said the Japanese company. The facility is due for completion in the 2023 Japanese fiscal year. The group aims to help commercialize 30% hydrogen and natural gas co-firing for large-frame gas turbines by 2025, and 100% hydrogen firing for small and mid-sized gas turbines. Takasago Hydrogen Park is smaller than other hydrogen projects under development around the world. However, it is reportedly the first example of a verification project that could facilitate future investments in hydrogen.

Fortescue Future Industries (FFI) has entered a strategic collaboration with Tree Energy Solutions (TES) to accelerate the development of a green energy import facility in Germany. FFI will invest €130 million ($127 million), while Netherlands Fortescue Future Industries Holdings B.V. will invest €30 million to become a shareholder in Tree Energy Solutions B.V., as well as €100 million in the construction of a TES terminal in Wilhelmshaven, Germany, said the company. It will also become a major shareholder with a 30% stake in Deutsche Grüngas und Energieversorgung GmbH, the project company that will build the TES Green Energy Hub in Wilhelmshaven, it added. The first delivery of green hydrogen into the terminal should occur in 2026. Initial collaboration projects will be focused on Australia, Europe, the Middle East, and Africa. The European energy infrastructure developer, led by Marco Alverà, is also developing a portfolio of terminals throughout the world. FFI is also making investments in Australia. Together with Incitec Pivot Ltd., it is considering converting an existing ammonia manufacturing facility near Brisbane to run on locally produced green hydrogen.

Lhyfe said it will develop a 200 MW green hydrogen production plant in Delfzijl, the Netherlands. The local industrial and chemical industry is already a large consumer of hydrogen as a chemical feedstock. “Delfzijl is an ideal location for renewable green hydrogen production as it has direct access to renewable energies from its offshore wind power plants, which are situated off the coast,” said Luc Grare, head of Central and Eastern Europe at Lhyfe. The region around Groningen aims to become the leading hydrogen hub for northwestern Europe, with a value chain ranging from green hydrogen production to storage and transportation. “Lhyfe's Delfzijl plant will be able to supply green hydrogen throughout the Netherlands, as well as to potential off-takers in Germany and other bordering countries,” said Grare.

ZeroAvia said this week that it has acquired HyPoint in full. The company, which develops solutions for zero-emission commercial aviation, did not disclose the financial terms of the deal. The acquisition of HyPoint will combine the fuel cell stack company's advanced high-temperature fuel cell technology with ZeroAvia's expertise.

Popular content

Fusion Fuel has entered into a technology sale agreement with Keme Energy to supply its solar-to-hydrogen system for a 1.22 MW green hydrogen project in Sines, Portugal. It expects to begin construction of the facility early next year and achieve commercial operation in the second half of 2023. The project, which is expected to produce an estimated 77 tons of green hydrogen per year, secured a €2.4 million grant from Portugal's Poseur program in late 2021.

Chemours and Advanced Performance Materials have announced a planned $200 million investment to increase capacity and advance technology for Chemours' Nafion ion exchange materials for the hydrogen economy. The proton exchange membranes are used in water electrolyzers, flow batteries and fuel cells.

The UK government said that England's Tees Valley area will host a competition to determine how hydrogen can be used for cleaner, more efficient transport. “The competition will address challenges such as refueling on a large scale, ensuring buses and coaches can use hydrogen in public transport ecosystems and how to make the supply chain greener with hydrogen-fueled HGVs,” it said.

The European Commission has approved a €1 billion German measure to help Salzgitter Flachstahl decarbonize its steel production processes by using hydrogen, including renewable hydrogen produced on site, thanks to a new production facility.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.